Due to the rapid development of intelligence (now high efficiency, high precision era), more and more stamping manufacturers now choose automated production lines for stamping production, because the material utilization rate can be greatly improved. Production in this way can reduce the labor loss of each process and improve the precision and production efficiency of processed products. However, these need to be punched with automatic material rack, precision leveling machine, automatic feeder to replace the original manual feeding to complete.

Because the?servo feeder?press?has a wide range of applications and is easy to install and debug, it is increasingly favored by many customers.?There are a lot of power press auto feeders nowadays (the?servo feeder press?is also called NC servo feeder press, NC feeder press).?Next, we will follow KINGLAN to learn the correct operation method of NC?servo feeder press:

1. Start the front machine supporting the production line (usually the leveling machine. In some occasions, if the material does not need to be leveled, it is a material frame), so that it can slowly release the material.

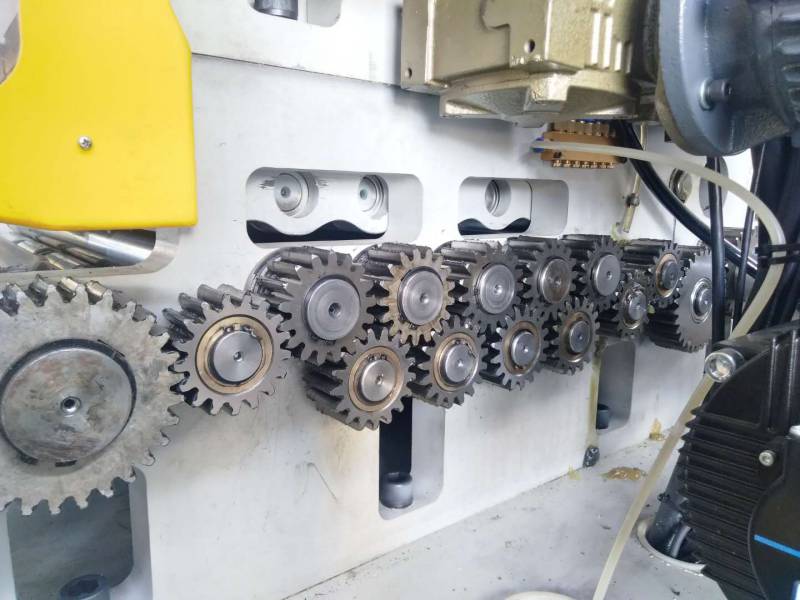

2. Feeder feeds and adjusts material thickness. Lift the feeder’s release handle, feed the material feed head between the upper and lower rollers of the feeder, let it pass through the roller, lower the release handle, and then loosen the fastening screw of the thickness adjustment handle,?adjust the handle up and down,Let the relaxation bracket keep the gap of about 5mm before and after the swing. After confirming the error, lock the fixing screws.

3. Adjust the feeding start time according to the actual stamping process requirements. The feeding time is actually the feeding angle, which is the angle at which the punching machine crankshaft starts to feed. The setting is very simple. Usually, you only need to input the punching angle of the feeding time on the punching touch screen.

4. Adjust the feeder relaxation device according to the requirements of the actual stamping process. The adjustment method is: when the inner guiding pin of the mold is inserted into the guiding hole, adjust the loosening screw so that it can touch the Palin on the main body of the feeding machine, so that the upper roller can leave the material within 0.5 mm and completely relax the material. After the confirmation is correct, the fixing nut can be locked.

5. Basic parameter setting of the feeder. After setting the feeding length and number of times on the panel of the electric control box, look at the actual situation and set the feeding speed accordingly.