Abstract: servo turret?

power press machine?is an indispensable NC machine tool in sheet metal processing, and the equipment will inevitably fail. In this paper, by observing the shape and size of burr after plate processing, material stripping and overshoot of hole distance during processing, and other common faults, the fault points and causes of equipment are preliminarily judged. And combined with common alarm information, the troubleshooting methods are summarized.

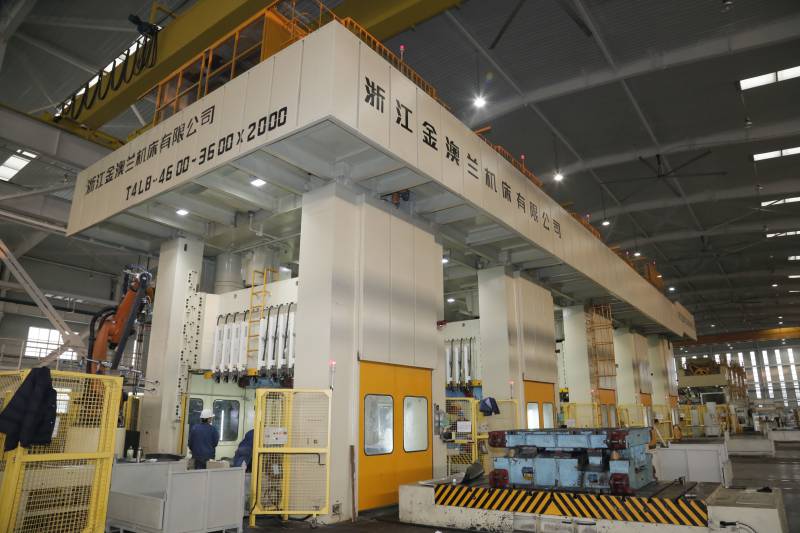

Turret power press machine is one of the necessary means of sheet metal processing. In recent years, servo turret power press machine has basically replaced mechanical press and hydraulic press. Servo turret power press machine has many practical advantages, such as energy saving, high efficiency, environmental protection and machinability to form complex shapes. Understanding the common fault causes of servo turret power press machines is helpful to the maintenance of the equipment, and it can solve the problem quickly and avoid downtime for long.

1. The burr is too big after plate processing

Under this situation, whether the clearance between the upper die and the lower die is suitable should first be checked. Usually the clearance between the two sides of the upper die and the lower die is 20%-25% of the thickness of the plate. Sometimes this happens when the plate is not replaced in time for the corresponding clearance of the lower die. Another possibility is that the die is blunt, and the edges of the upper die and the lower die can be observed. If there are obvious rounded corners, it is necessary to grind the die or replace a new set of moulds. Generally, if the grinding depth of the lower die exceeds 0.5 mm, gaskets will be needed. The depth of grinding generally does not exceed 1 mm.

If there are burrs on the half side of the sheet metal, it is suggested that there are deviation of the alignment of the upper and lower dies. At this time, it is generally necessary to contact the manufacturer after sales service to adjust the alignment with the special mandrel.

2. The knife which is cut through rotary die has burrs.

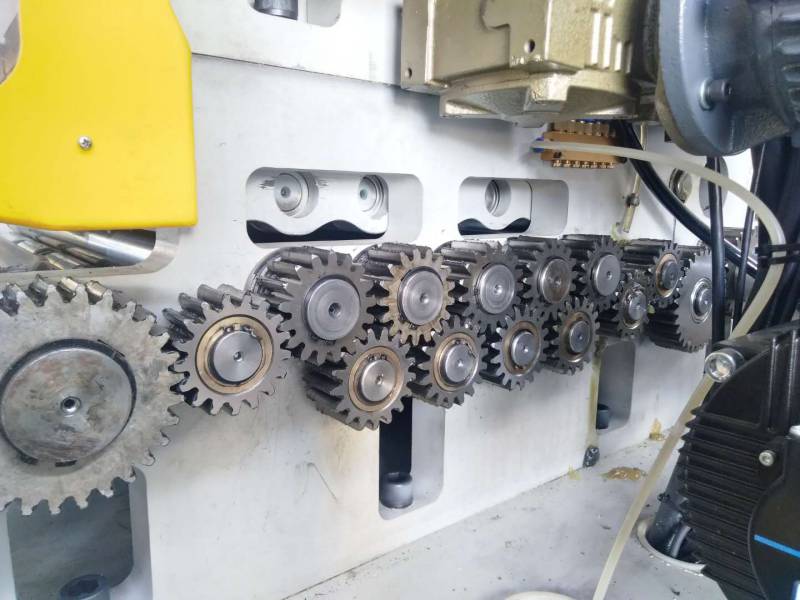

At present, the rotating die structure of turret power press machine on the market can be mainly divided into two kinds: one structure is typical characterized that the worm wheel and worm deceleration direct drive die base, which is installed in the follower of the docking fork, moves with the turntable; the typical feature of the other structure is that worm wheel and worm reducer is installed in the active side of the docking fork. Structurally speaking, the first kind of rotating die has higher precision.

The reason that there’s burr in the cutting edge is that the angle of the cutting tool in the rotary die punching is not perpendicular to the feed. There are many possibilities for this phenomenon. According to the different structure of the rotary die, the inspection is different. The first type of rotating die structure needs to check whether the driving belt of the rotating die is too loose, whether the expansion sleeve of the pulley is loose, and whether the coupling connecting screw is loose. Besides the possible problem of the first type, the second type needs to check the concentricity of the connecting fork and the clearance between the sleeve and the fork.

3. pulling material

There are three main possibilities for pulling material. The direct consequence of pulling material may be scrap of sheet metal or even damage of equipment.

(1) When the punch does not return to the upper dead point, the sheet metal moves. At this time, it is necessary to check whether the upper dead-point switch of the power head is normal and whether the system program has been changed.

(2)stripping: Punch can not pull the sheet material out of the sheet metal, and the sheet metal moves. The stripping is due to insufficient unloading force. When the die goes up, the punch can not withdraw from the sheet metal, and the sheet metal goes up together. This kind of situation generally has the omen. When you discover that the sheet blanking has abnormal noise, it has the phenomenon of stripping, so you need to take the following measures promptly: ①use the bigger punch with additional inverted cone. ②Increase the upper die clearance. ③Check the strain degree of unloading spring and replace it when necessary. ④use die with sharp edge. ⑤Use heavy-duty die. ⑥Lubricate plate. ⑦adopy large workstations.

(3) Scrap rebound: The scrap is stuck between the sheet metal and the die, and the sheet metal moves. Waste rebound can be prevented and solved by the following measures: 1. Push rubber column should be installed on the end face of punch, and it should be replaced in time without missing. 2. Clean up the oil on the board. 3. Complete demagnetization of the die. 4. Reduce stamping frequency properly.5. Increase the modulus. 6. Use anti-rebound die. 7. Increase the gap between upper and lower dies.

4. Over-tolerance of hole spacing

First, observe which direction is out of tolerance, and check whether the expansion sleeve of the coupling and pulley of the lead screw is loose in the direction of out-of-tolerance; if the equipment is used for a long time, check the accuracy of the lead screw and the clearance between the die and the turntable; at the same time, check the set parameters, such as speed gain, speed loop integral gain, speed loop proportional gain, load inertia ratio and servo. Whether the gain of position loop meets the actual requirements or not, if not, the corresponding parameters need to be adjusted according to the waveform.

5. Solutions to Several Common Alarm Problems

(1) The switch signal is not in place, which may be the reason that the switch is loosening so that it is displaced; or the switch wiring has problems. Please check the line.

(2) The piercing accuracy is not stable, and the servo axis of the machine tool is sometimes fast and sometimes slow in the course of operation. The reason for this phenomenon is that the parameters are not set correctly. It is necessary to check the settings of acceleration and deceleration and whether each gain meets the actual needs according to the waveform.

(3) No alarm, no response to return to the origin. In general, the cause of this situation is that it is not in the position of the rotating die. Because when the machine tool returns to the reference point for the first time, it needs to move the rotating die shaft. If the rotating die shaft can not move, it will wait all the time.

6. conclusion

The above description is the fault and cause analysis which is common and generally exists. There are many small faults that need specific analysis.