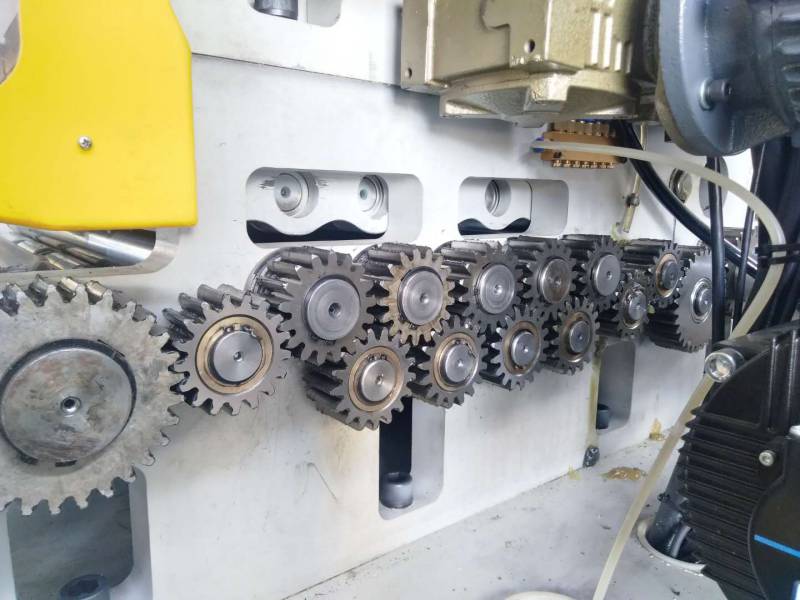

The split stamping production line includes a bump-cutter machine, a feeder and a material rack. While the?3 in one feeders?is a fully automatic device includes feeding, rectifying and rack. It combines the functions of unwinding, leveling and feeding into one machine. The single machine can be combined with the punch to form a short process stamping automation production line. What is the difference between the two?

1. The difference in the space occupied by the layout of the production line. KINGLAN three-in-one feeder combines the three functions of unwinding, leveling and feeding. No matter what kind of material, there is no need to reserve the waiting area separately. The occupied space is the size of the machine itself. Usually 4- 5 meters.

For the split stamping automatic production line, the material frame, the leveling machine and the feeder must be reserved areas, and the thicker the material, the longer the feeding step, the larger the required waiting space, especially the thick plate. Material stamping often requires a reserve area of about 3 meters between the material rack and the leveling machine, the leveler and the feeder, making the overall production line occupy large space.

2. The difference in production line debugging. KINGLAN 3 in one servo feeder short-circuit stamping production line is extremely simple to use, basically only need to connect the power supply, you can complete the debugging by operating the control operation on the touchscreen, then you can test the machine.

For the split type stamping automatic production line, it is necessary to manually introduce, feed and debug the three types of machine racks, leveling machine and feeder. The use is extremely cumbersome and requires a lot of manpower and material resources. Especially when using wide plates and heavy rolls, simple feeding and feeding processes require multiple people to assist the traction and often use crowbars to assist, not only easy to injure and easily cause machine damage.

3.Differences in the operation of the production line. KINGLAN three in one servo feeder operation can be easily completed through a touchscreen and handle, which can automatically realize loading, pressing, feeding, feeding, folding, leveling and feeding functions, and the operation is extremely simple.

For the split type stamping automatic production line, it is necessary to independently introduce, feed, block, operate, and test, which are completely separate operations, and the operation is relatively cumbersome.